In today’s fast-paced manufacturing landscape, companies must innovate quickly while maintaining high levels of precision and cost-effectiveness. One of the most impactful technologies driving this evolution is CNC machining services. Short for Computer Numerical Control, CNC machining transforms digital designs into high-precision parts and prototypes. This technology has revolutionized product development by offering unparalleled accuracy, repeatability, and speed. Businesses across various sectors—from automotive to aerospace, medical devices to consumer electronics—rely on CNC machining services to streamline their development process and accelerate time-to-market.

Understanding CNC Machining Services in Product Development

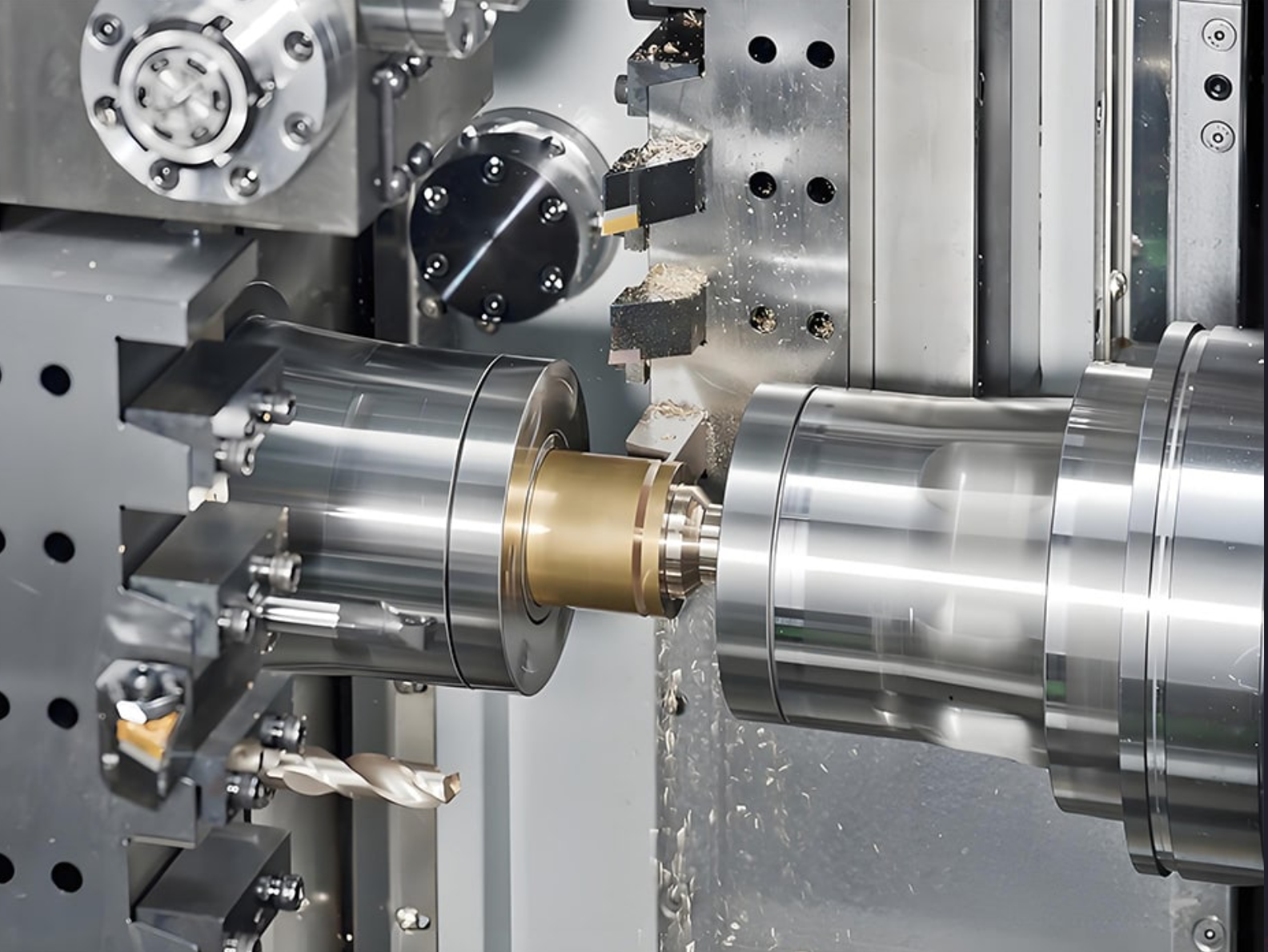

CNC machining services involve the use of pre-programmed computer software to control machinery tools such as lathes, mills, routers, and grinders. These machines cut and shape raw materials like metal, plastic, wood, and composites into exact specifications. By automating the production process, CNC machining ensures consistent, high-quality outputs that are difficult to achieve with manual processes.

Unlike traditional manufacturing techniques, CNC machining enables rapid transitions from design to prototype without the need for expensive tooling. This is especially beneficial during the early stages of product development, where flexibility and precision are essential.

Speeding Up the Prototyping Phase

One of the most significant ways CNC machining services enhance product development efficiency is by speeding up the prototyping phase. Traditionally, developing a prototype could take weeks or even months due to manual labor, mold creation, or custom tooling. CNC machining cuts this timeline drastically.

Engineers can now create functional prototypes in a matter of hours or days. This quick turnaround allows for multiple iterations, enabling designers to test, refine, and validate their ideas swiftly. With faster prototyping, teams can detect and resolve design flaws early in the process, reducing costly changes later in development.

Precision and Repeatability

Accuracy is crucial in product development, especially when creating parts that require tight tolerances. CNC machining services offer a level of precision that is almost impossible to replicate with manual methods. Whether producing a single prototype or a short production run, the machines maintain consistent results across all parts.

Repeatability is another essential advantage. Once the digital file is created and programmed into the machine, it can be reused indefinitely to produce identical parts, ensuring uniformity across production batches. This is particularly valuable for industries where safety and compliance standards are strict, such as aerospace or medical devices.

Cost-Effective Small-Batch Production

While CNC machining may have higher upfront costs than some other manufacturing techniques, it becomes cost-effective for small and medium-scale production. There’s no need to invest in expensive molds or dies, and setup times are significantly reduced. This allows companies to produce limited quantities of components without incurring excessive costs.

CNC machining services also reduce material waste. Since the machines cut with high precision, they minimize the amount of excess material, which is especially important when working with expensive metals or specialty plastics. Efficient material usage directly contributes to cost savings and environmental sustainability.

Flexibility in Material Choices

Another notable benefit of CNC machining services is the broad range of materials that can be used. From aluminum and titanium to engineering-grade plastics like PEEK and Delrin, CNC machines handle a wide variety of materials with ease. This flexibility allows product designers to explore different material options for strength, weight, heat resistance, and aesthetics.

By testing prototypes in different materials early in the development cycle, teams can make informed decisions about the final product’s design and performance. This not only saves time but also ensures the end product meets both functional and budgetary requirements.

Seamless Integration with CAD/CAM Software

Modern CNC machining services are tightly integrated with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. This integration allows for a seamless transition from digital design to physical part. Engineers can upload 3D models directly into the machining software, which then generates toolpaths and machine instructions automatically.

This reduces the risk of human error and ensures the finished product closely matches the original design. The ability to make quick adjustments to digital files also enhances agility, enabling teams to adapt quickly to design changes or new customer requirements.

Supporting Complex Geometries and Customization

Advanced CNC machining services can create parts with intricate geometries that would be difficult or impossible to achieve with traditional tools. Multi-axis machines, for example, allow for simultaneous cutting on multiple planes, enabling the creation of complex shapes in a single setup.

This capability is particularly advantageous when developing custom parts or products with unique specifications. Whether it’s a customized medical implant or a high-performance automotive component, CNC machining delivers the flexibility to bring highly detailed and specialized designs to life without extensive manual intervention.

Accelerating Time-to-Market

In highly competitive markets, being the first to launch a new product can make all the difference. CNC machining services help shorten development cycles, allowing companies to move from concept to production faster. By minimizing prototyping delays, reducing rework, and enabling rapid iterations, CNC machining accelerates every phase of the product development timeline.

This speed not only benefits internal teams but also improves customer satisfaction. Clients and stakeholders receive prototypes and finished parts faster, improving communication, gaining quicker feedback, and fostering stronger relationships.

Enhancing Quality Control

Quality assurance is built into every step of the CNC machining process. Since machines operate based on exact specifications, there is minimal room for deviation. In addition, many CNC service providers employ rigorous inspection techniques, such as Coordinate Measuring Machines (CMMs), laser scanning, and other advanced metrology tools.

These systems verify that each part meets predefined standards and tolerances. Early detection of defects ensures that issues are corrected before full-scale production begins, maintaining product integrity and reducing the risk of recalls or failures.

Scalability and Long-Term Reliability

CNC machining services offer scalability, which means a successful prototype can be quickly scaled into full production using the same digital files and setup. This consistency ensures that the quality and functionality of the product remain unchanged as volume increases.

Furthermore, CNC machining’s durability and long-term reliability make it a preferred choice for companies planning to maintain product lines over extended periods. The ability to produce replacement parts or updates without retooling adds tremendous value for both manufacturers and end users.

Conclusion

CNC machining services have become a cornerstone of modern product development, offering unmatched speed, precision, and flexibility. By streamlining prototyping, supporting design complexity, enabling rapid iteration, and reducing waste, CNC machining enhances efficiency at every stage of the development process.