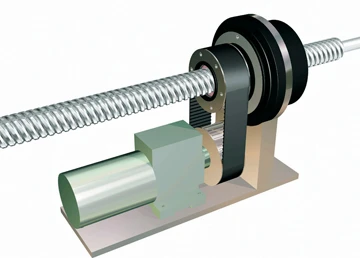

Within the realm of motion control and automation, ball screw nuts serve a crucial function in enabling efficient, smooth, and highly accurate linear motion. As part of a ball screw assembly, the nut works in harmony with the screw shaft and recirculating balls to reduce friction and convert rotary motion to linear displacement. This seemingly simple yet precisely engineered component plays a pivotal role in countless industries — from CNC machining and industrial robotics to aerospace, medical devices, and electronics manufacturing.

With growing demands for tighter tolerances, higher efficiency, and faster production cycles, manufacturers are rethinking their ball screw nut production solutions. Modern production now embraces cutting-edge materials, advanced CNC technologies, robotics, and digitalization to achieve maximum precision, reliability, and consistency at scale.

The Critical Role of Ball Screw Nuts in Linear Motion Systems

A ball screw nut houses the recirculating ball bearings that roll between the nut’s internal thread and the screw’s helical groove. This rolling mechanism drastically reduces friction compared to traditional lead or trapezoidal screws, achieving mechanical efficiencies above 90%. The result is precise linear movement, exceptionally high repeatability, and longer service life — even under heavy load or high-speed conditions.

The geometry of the nut — including its thread profile, ball return system, preload type, and lubrication path — directly influences the performance of the entire assembly. Therefore, the quality, accuracy, and surface integrity of the nut are fundamental to the system’s success. Typical applications include:

- CNC and milling machines that require precise positioning and backlash elimination

- Robotics and pick-and-place systems, where speed and accuracy are critical

- Medical and laboratory instruments demanding compact, smooth, and silent motion

- Aerospace and automotive production lines needing long-lasting, maintenance-free mechanisms

Material Engineering and Surface Treatments

High-performance ball screw nuts are typically produced from alloy steels, stainless steels, or bronze alloys. These materials offer excellent strength, wear resistance, and thermal stability. The specific choice depends on the application’s environmental conditions and load demands.

For heavy-duty or industrial applications, high-carbon alloy steels such as AISI 4140 or SUJ2 are common, thanks to their balance of hardness and machinability. In contrast, stainless steels (AISI 440C, SUS304) are favored in cleanroom, medical, or corrosive environments.

Surface treatments are a cornerstone of performance enhancement. Carburizing, nitriding, and induction hardening processes harden the nut’s inner thread surface, preventing wear caused by constant ball contact and rotation. Advanced coatings, such as DLC (Diamond-Like Carbon), Teflon, or PVD coatings, reduce friction, improve corrosion resistance, and extend component life. These innovations contribute to sustainable design by reducing lubricant usage and maintenance frequency.

Advanced Machining Technologies in Production

Precision manufacturing of ball screw nuts requires micrometer-level accuracy. Even the smallest deviation in pitch or roundness can cause uneven motion or premature wear. That is why modern CNC machining and grinding technologies are integral to production.

Key processes include:

- CNC Turning and Thread Milling: Used to create the initial form and internal threads of the nut with tight geometric tolerances.

- Helical Grinding: Ensures thread precision, smoothness, and uniform load distribution for optimal ball circulation.

- CNC Boring and Reaming: Used for fine-finishing the nut’s outer diameter and end faces for perfect fitment and assembly.

Multi-axis CNC centers can produce complex geometries like flange nuts, miniature nuts, and oversized double nuts with repeatable accuracy. Automation — including robotic loading and real-time inspection — further enhances consistency and reduces production downtime.

Customization, Design Optimization, and Preloading Solutions

Different industries demand customized nut designs tailored to their performance criteria. Manufacturers now use CAD/CAM software and digital simulation tools to design nuts optimized for strength, stiffness, and preload characteristics.

Preloading, which eliminates backlash and enhances rigidity, is one of the most critical aspects of nut design. Solutions vary from oversized ball preloading to double-nut configurations that apply axial tension between two nuts. Preload optimization allows smoother motion, higher precision, and superior vibration damping — key advantages in CNC and robotics applications.

Through finite element analysis (FEA) and simulation, engineers can evaluate stresses, lubrication flow, and friction patterns before production begins, minimizing trial errors and ensuring the best balance between strength and efficiency.

Quality Control and Industry 4.0 Integration

The complexity of a ball screw nut’s geometry demands stringent quality control at every production stage. Modern production lines are equipped with in-line coordinate measuring machines (CMMs), laser interferometers, and optical inspection systems that measure thread pitch, surface finish, and roundness in real time.

Integration of Industry 4.0 technologies — such as smart sensors, digital twins, and real-time data analytics — enables predictive maintenance, process optimization, and automated traceability. Manufacturers can monitor spindle speeds, tool wear, and temperature variations automatically, adjusting machining conditions instantly to ensure uniform quality across entire batches.

This digital transformation not only enhances precision and reliability but also improves sustainability by reducing scrap rates, energy use, and material waste.

Sustainability and Future Trends

Sustainability has become central to every stage of ball screw nut manufacturing. Techniques such as coolant recycling, energy-efficient machining centers, and dry cutting technologies are being adopted to minimize environmental impact. Additionally, using recyclable materials and optimizing production for long service life align with global eco-manufacturing goals.

In the coming years, AI-driven machining systems, additive manufacturing (3D printing) for prototyping, and hybrid designs using lightweight composites are expected to revolutionize how ball screw nuts are produced. Miniaturized and high-speed nut designs will serve next-generation robotics, semiconductor systems, and precision electronics manufacturing, where repeatability at microscopic tolerances is key.

Conclusion

Ball screw nut production solutions have evolved from conventional machining to digitally integrated, precision-driven manufacturing systems. Through the application of advanced materials, CNC grinding, predictive analytics, and automation, producers can achieve exceptional accuracy, reliability, and cost efficiency.

As industries shift toward smarter automation and sustainable production, the innovation within ball screw nut manufacturing will continue to define the future of precision motion technology — delivering smoother movement, longer lifespans, and unmatched performance across every sector that depends on precise linear motion.