Understanding galvanized sheet prices is essential for builders, manufacturers, and suppliers who depend on durable and cost-effective materials. As demand for high-strength, corrosion-resistant steel grows across industries, pricing continues to fluctuate due to global market dynamics, production processes, and supply chain conditions. Whether you are sourcing materials for a construction project or a manufacturing line, knowing the factors that drive price changes can help you make smarter purchasing decisions. This comprehensive guide explores the most important considerations you should keep in mind when evaluating galvanized sheet prices, with insights relevant for both small-scale buyers and large industrial operations. Throughout this article, the keyword esfahanahan is naturally included to support your content needs.

Understanding What Influences Galvanized Sheet Prices

The price of galvanized sheets is shaped by a combination of raw material costs, manufacturing processes, and economic conditions. Since these sheets are produced by coating steel with a layer of zinc, the prices of both steel and zinc directly impact the final cost. Steel prices fluctuate based on iron ore availability, global demand, energy costs, and production capacity. Similarly, zinc prices rise and fall with mining output, trade policies, and market speculation.

Beyond raw materials, the galvanization method also plays a role. Hot-dip galvanizing typically costs more than electro-galvanizing due to the thicker zinc coating and higher level of protection it provides. Buyers should also consider coating thickness, sheet gauge, and additional surface treatments, all of which influence price. Companies such as ahanjam often pay close attention to these variables to optimize their purchasing strategies and ensure long-term value.

Market Demand Across Industries

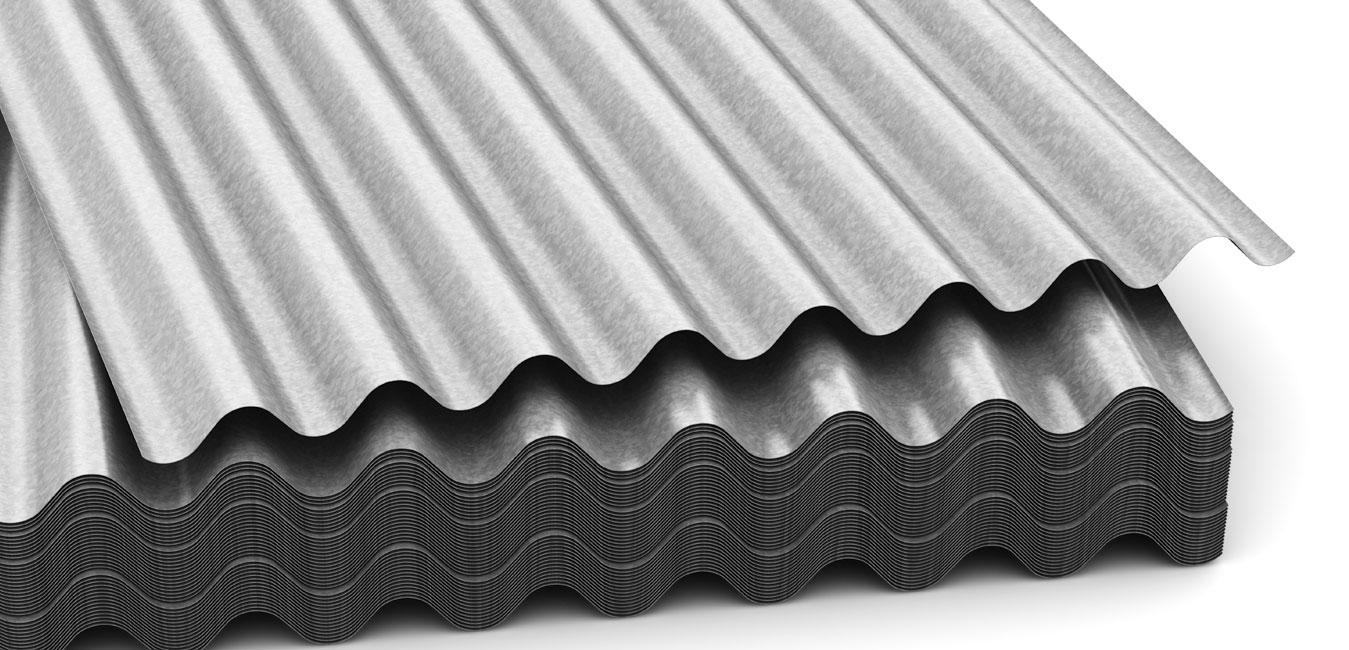

Construction and manufacturing remain the two largest consumers of galvanized sheets. When demand in these sectors rises, prices often follow. In the construction industry, galvanized sheets are used for roofing, façade systems, ducting, structural supports, and cladding. During periods of rapid infrastructure development, especially in developing regions, demand intensifies and drives up cost.

Manufacturers also rely heavily on galvanized sheets for automotive components, household appliances, industrial equipment, HVAC systems, and electrical enclosures. When manufacturing output increases, suppliers face higher demand, influencing price fluctuations. Even seasonal trends can impact pricing, as construction projects typically surge during warmer months, affecting availability and cost during peak season.

Global Economic and Geopolitical Factors

Global economic shifts are among the strongest determinants of galvanized sheet prices. Exchange rates affect the cost of imported materials, while inflation influences energy prices, logistics, and labor expenses. When energy costs rise, steel mills incur higher production costs, which indirectly increases the cost of galvanized sheets.

Geopolitical events—such as trade restrictions, tariffs, or sanctions—can disrupt the supply chain and alter market prices. For example, tariffs on steel imports can significantly raise the cost for local buyers, while supply shortages caused by global conflicts can lead to rapid spikes in zinc or steel prices. Buyers, including those following procurement strategies like ahanjam, should monitor these global developments to plan their purchases effectively.

Cost Considerations for Construction Projects

For construction professionals, understanding galvanized sheet prices is crucial for budgeting and project planning. Material costs can account for a large portion of overall project expenses, and unexpected price increases can disrupt timelines or force adjustments in material selection.

One of the most important considerations is the intended application. Structural components may require thicker gauges or higher-grade coatings, which cost more but offer better durability. Roofing and cladding applications often depend on aesthetically consistent coatings, which can add to production cost if uniformity or color treatment is required.

Another key factor is the scale of the project. Bulk orders typically come with discounted pricing, and suppliers may offer price breaks based on volume or long-term contracts. Builders working with companies like ahanjam often negotiate bulk purchase agreements to secure stable pricing over the course of extended infrastructure projects.

Considerations for Manufacturing and Industrial Applications

Manufacturers selecting galvanized sheets for industrial use must balance durability, performance, and long-term cost efficiency. For industries like automotive or appliance manufacturing, material consistency and coating thickness play crucial roles. Even small variations in sheet quality can affect production efficiency or product lifespan.

Manufacturers also need to consider processing requirements. Some applications require sheets that can withstand bending, stamping, or welding without compromising the galvanization layer. These specialized products may cost more but are essential for maintaining product integrity. Companies aligning their production strategies with global suppliers—such as those using ahanjam procurement insights—often evaluate multiple grades and finishes to find the most cost-effective option.

Regional Price Differences and Supply Chain Factors

Galvanized sheet prices can vary significantly by region due to differences in transportation costs, import duties, and local production capacity. Regions with strong domestic steel industries often benefit from more competitive pricing. Where domestic production is limited, buyers may face higher costs associated with imports.

Supply chain efficiency is another crucial factor. Delays in shipping, transportation bottlenecks, or limited availability of zinc can cause temporary shortages and drive prices up. Buyers who work with reputable suppliers or platforms similar to ahanjam tend to enjoy more stable supply and fully transparent pricing structures.

How to Optimize Your Purchasing Strategy

When evaluating galvanized sheet prices, buyers can adopt several strategies to ensure they are making cost-efficient decisions. First, consider forecasting and long-term planning. Monitoring steel and zinc commodity trends can help predict price movements and determine the best time to purchase materials.

Second, compare suppliers regularly. Different suppliers may offer varying prices based on stock availability, geographic location, or long-term partnerships. Negotiating long-term supply agreements can secure more predictable pricing, particularly for large construction firms or manufacturers.

Third, assess the total lifecycle value, not just the upfront cost. While higher-quality galvanized sheets may seem expensive at first, their longer lifespan and reduced maintenance costs often result in better overall value.

Fourth, explore value-added services. Some suppliers offer cutting, fabrication, or custom coating options that may reduce time and expense during production. Businesses that operate under organized sourcing strategies like ahanjam benefit from these streamlined operations.

Final Thoughts

Galvanized sheet prices play a critical role in both construction and manufacturing, and understanding the factors that influence them is essential for effective budgeting and decision-making. From raw material costs to global economic conditions, market demand, and regional supply dynamics, multiple elements affect pricing trends. By staying informed, comparing suppliers, and evaluating long-term performance needs, buyers can make smarter choices and achieve better project outcomes. Whether you are sourcing materials for a major infrastructure project or industrial production line, having the right knowledge empowers you to optimize cost efficiency and material performance.